COMPOSITE MATERIALS

The MDI vehicles manufactured are exceptional achievements using disruptive technology based on compressed air and composite materials.

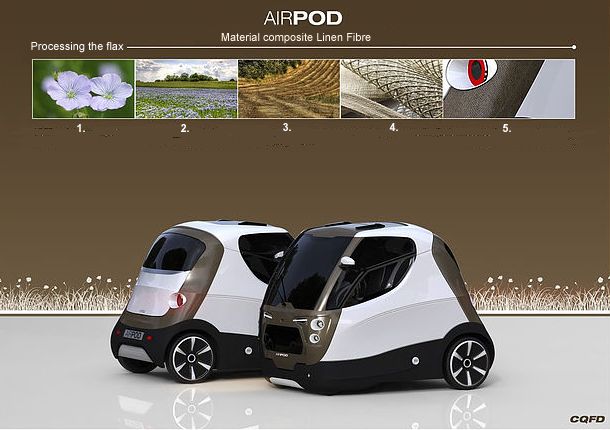

The body of the AirPod is made from linen fibres. March 4, 2016

“Ecology will have real impact on our planet if it is accessible to all.“

1. Flower 2. Field 3. Harvest 4. Weaving 5. Finished Product

COMPOSITE MATERIALS

LIGHT & RESISTANT

Composite technology

The bodies are a foam sandwich construction. A 20 mm thick polyurethane moulding sandwiched between two 3mm thick layers of fibreglass.

The result is a light, stiff and strong body, the same as what high end manufacturers seek.

To manufacture the body parts, Resin Transfer Moulding (RTM) is used. Epoxy is the resin used for the body parts, with woven fibreglass as the reinforcing.

The fibreglass reinforcement is placed into the open mould, the mould is closed ready for the mixed resin to be injected into the mould. The resin and catalyst are pumped to a mixing head, then injected into the mould, which is vented to ensure the part is fully filled. When the cure time has elapsed, the mould is opened and the cured part removed.

These processes are all ideal to match the production rates required in low volume local factories.

Watch Video

Watch Video